What is Central HVAC System?

A central HVAC system may serve one or more thermal zones, and its major

equipment is located outside of the served zone(s) in a convenient central

location, whether inside, on top of, or adjacent to the

structure.

advertisement

Zones must be a condition with their equivalent thermal load by central

systems. Each zone of a central HVAC system will have multiple control

points, such as thermostats. The central HVAC system is divided into

subcategories based on the medium used in the control system to provide

thermal energy.

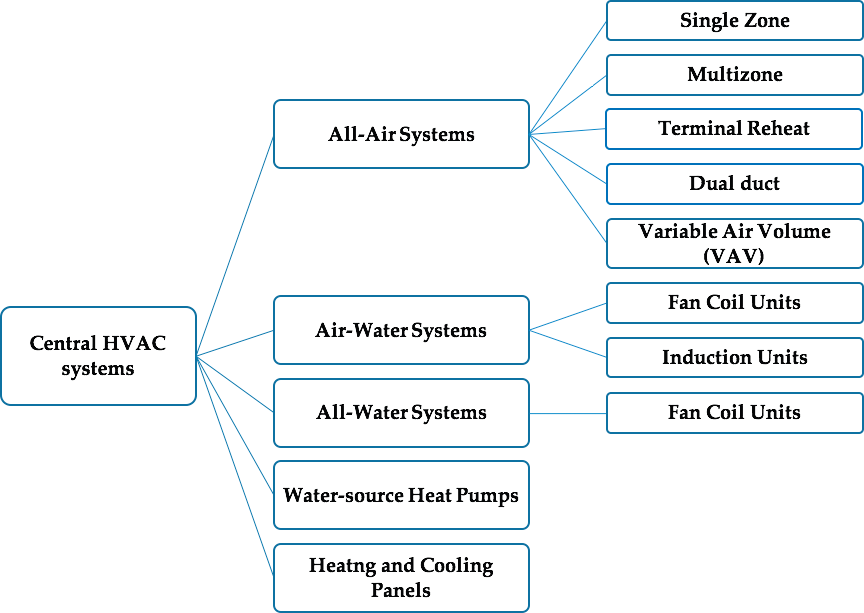

What are the types of Central Hvac Systems?

advertisement

Air, water, or both can be used as the thermal energy transfer medium,

resulting in all-air, air-water, and all-water systems. Water-source heat

pumps and heating and cooling panels are also included in central systems.

The following sections go over each of these subsystems.

Supply and return air fans, humidifier, reheat coil, cooling coil, reheat

coil, mixing box, filter, and outdoor air are all included in a central HVAC

system's air handling unit.

All-air systems

advertisement

Air serves as the thermal energy transfer medium in building delivery

systems. All-air systems can be divided into single zone and multizone

systems, as well as constant and variable airflow rates for each zone,

terminal reheat, and dual duct systems.

Single Zone:

An air handling unit, heat and cooling source, distribution ductwork, and

appropriate delivery devices make up a single zone system. Where heat and

cooling sources are available, the air handling units can be fully

integrated, or they can be separated where heat and cooling sources are not

available. The most common integrated package is a rooftop unit connected to

ductwork to deliver conditioned air to multiple spaces in the same thermal

zone.

Single-zone systems have the advantage of being simple to design and

maintain, as well as having a low initial cost when compared to other

systems. However, when improperly applied, its main disadvantage is that it

only serves a single thermal zone.

advertisement

One control device, such as a thermostat located in the zone, controls the

operation of a single zone all-air HVAC system, as shown in Figure. To meet

the single zone's required thermal load, the control can be modulating or

on–off. This can be accomplished by adjusting the output of the packaged

unit's heating and cooling sources.

Despite the fact that only a few buildings can have a single thermal zone,

a single zone can be used in a variety of applications. Residential

buildings with only one family can be treated as single zone systems,

whereas other types of residential buildings can have varying levels of

thermal energy depending on the occupation and structure.

advertisement

The thermal load of the building is affected by occupant movements,

resulting in the division of the building into several single zones to

provide the required environmental condition. This is especially noticeable

in larger homes, where two (or more) single zone systems may be used to

provide thermal zoning. Each apartment unit in a low-rise building may be

cooled by a separate single zone system. A series of single zone systems can

effectively condition many large single storey buildings, such as

supermarkets and discount stores. A series of separate single zone systems

may be used to cool large office buildings.

Multi-Zone:

Individual supply air ducts are provided for each zone in a multi-zone

all-air system. To meet each zone's thermal requirements, cold and hot (or

return) air are mixed at the air handling unit. As shown in Figure, each

zone's conditioned air cannot be mixed with that of other zones, and

multiple zones with different thermal requirements require separate supply

ducts. An air handling unit with parallel flow paths through cooling and

heating coils, as well as internal mixing dampers, makes up a multi-zone

all-air system. Because of physical constraints on duct connections and

dampers, it is recommended that one multi-zone serve a maximum of 12

zones.

Additional air handlers may be used if more zones are required. The

multi-zone system has the advantage of adequately conditioning multiple

zones without the energy waste associated with a terminal reheat system.

Leakage between the decks of an air handler, on the other hand, may reduce

energy efficiency. The main drawback is that multiple supply air ducts are

required to serve multiple zones.

Terminal Unit:

advertisement

A terminal reheat all-air system is a multiple zones that considers

an adaptation of a single zone system. This can be accomplished by

installing heating equipment downstream of the supply air from air handling

units near each zone, such as a hot water coil or an electric coil. A

thermostat controls each zone, adjusting the heat output of the heating

equipment to match the temperature. The terminal reheat adds the required

heating load to the supply air from air handling units, which is cooled to

the lowest cooling point.

Terminal reheat has the advantage of being adaptable, as it can be

installed or removed to accommodate changes in zones, allowing for better

thermal control in multiple zones.

However, the terminal reheat system is not an energy-efficient system

because a large amount of extremely cooling air is not required on a regular

basis in zones, which can be considered waste energy. As a result, reheat

system use is governed by energy codes and standards.

Dual Duct:

advertisement

A terminal-controlled variation of the multi-zone concept is the dual

duct all-air system. A central air handling unit produces two conditioned air streams, one

cold and one hot. Separate and parallel ducts are used to distribute these

air streams throughout the area served by the air handling

unit.

Each zone has a terminal mixing box that is controlled by the zone

thermostat and adjusts the supply air temperature by mixing cold and hot

supply air. By utilising terminal control, this system will reduce the

drawbacks of previous systems while increasing flexibility.

Variable Air Volume:

Due to changes in thermal loads, some spaces require a different supply

airflow.

As a result, for achieving thermal comfort, a variable-air-volume (VAV)

all-air system is the best option. Constant volume systems are the first

four types of all-air systems.

The VAV system is made up of a central air handling unit that supplies

supply air to each zone's VAV terminal control box, which controls the

supply air volume. The supply air flow rate is used to control the

temperature of each zone's supply air.

The main drawback is that the controlled airflow rate can have a negative

impact on adjacent zones with different or similar airflow rates and

temperatures. In addition, part-load conditions in buildings may

necessitate a low air-flow rate, which reduces fan power and saves energy.

It may also reduce ventilation flow rate, which can be problematic for the

HVAC system and have an impact on the building's indoor air quality.

All - Water System:

advertisement

Heated and cooled water is distributed from a central system to conditioned

spaces in an all-water system. This system is smaller than others due to the

use of pipes as distribution containers and the fact that water has a higher

heat capacity and density than air, requiring a smaller volume to transfer

heat. Floor radiators, baseboard radiators, unit heaters, and convectors are

among the delivery devices used in all-water heating systems. However,

all-water cooling systems, such as valance units mounted in the ceiling, are

uncommon. A fan-coil unit is the most common type used in buildings to

condition the entire space.

Fan-Coil Unit:

A fan-coil unit is a small unit that includes a circulation fan, heating

and cooling coils, and a proper control system. The unit can be mounted

vertically or horizontally. Because the fan-coil unit can be placed in the

room or exposed to the occupants, it is critical that it be finished and

styled properly.

The fan-coil units are connected to boilers to provide heating and to water

chillers to provide cooling to the conditioned space in central systems. A

thermostat detects the desired temperature of a zone and controls the water

flow to the fan-coil units. In addition, occupants can control the

temperature of fan coil units by adjusting supply air louvers. The main

disadvantage of fan-coils is the lack of ventilation air, which can only be

overcome if the fan-coil units are connected to the outside air. Another

disadvantage is the level of noise, which is especially problematic in

sensitive areas.

Air- Water System:

Air-water systems are a hybrid system that combines the benefits of both

all-air and all-water systems. To properly condition the desired zone, the

volume of the combined is reduced, and outdoor ventilation is produced. The

water medium is responsible for carrying 80–90% of a building's thermal load

through heating and cooling water, while the air medium is responsible for

the remainder. Induction units and fan-coil units are the two main

types.

Fan Coil Unit:

Air-water fan-coil units are similar to all-water fan-coil units, with the

exception that supply air and conditioned water are delivered to the desired

zone from a central air handling unit and central water systems,

respectively (e.g., boilers or chillers). The ventilation air can be

delivered into the space separately or linked to the fan-coil units. The two

most common fan-coil systems are two-pipe and four-pipe systems.

Induction Unit:

Externally, induction units resemble fan-coil units, but they are

internally distinct. An induction unit uses high-velocity airflow from a

central air handling unit to induce air flow in a room through a cabinet,

replacing the forced convection of the fan in the fan-coil with the

induction or buoyancy effect of the induction unit. This can be accomplished

by combining primary air from the central unit with secondary air from the

room to create a suitable and conditioned air in the room/zone.

Heat pumps with a water source:

In extreme cold weather, water-source heat pumps are used to provide

significant energy savings for large buildings. Because each heat pump can

be controlled according to the zone control, a building with multiple

zones can be conditioned by several individual heat pumps. Heat pumps can

use a centralised water circulation loop as both a heat source and a heat

sink. Heat pumps can thus be used as the primary source of heating and

cooling. The main disadvantage, similar to all-water systems and fan-coil

units, is the lack of air ventilation.

advertisement

Panels for heating and cooling

Heating and cooling panels are mounted on the floor, walls, or ceilings

where they can provide heat and cool. Radiant panels are another name

for it. The cooling or heating media is circulated into the tubes to

cool or heat the surface in this type of system, which can be built as

tubes or pipes impeded inside the surface. To achieve the desired

surface temperature for the cooling and heating processes, the tubes are

contacted to the adjacent large surface area. Radiation between the

occupants and the radiant panels, as well as natural convection between

the air and the panels, are the primary modes of heat transfer.

To achieve thermal comfort for occupants, radiant floor panels should be

restricted to a temperature range of 66–84°F (ASHRAE Standard 55). For

cooling and heating, radiant ceiling or wall panels can be used. To avoid

condensation on the surface during the cooling process, the surface

temperature should be higher than the air dew point temperature.

Furthermore, the maximum surface temperature for ceiling levels at 10 ft.

is 140°F, and for ceiling levels at 18 ft., it is 180°F. This temperature

is recommended to avoid excessive heating above the heads of the

occupants.

Although such systems are more expensive to instal than the other types

mentioned above, they can be useful and have a lower operating cost due to

the surface temperature restriction. Each zone's thermostat is connected

to a control signal that manipulates the medium temperature to condition

the space. To prevent icing inside the tubes during the cooling process,

the used medium can be refrigerant or water mixed with inhibited glycol

instead of plain water. The main benefit is that no additional space is

required; the panels only need to be installed a few inches apart, and no

dirt is collected in the standard ceiling or ductwork. There are a variety

of designs to choose from when creating attractive panels.

1 Comments

Good

ReplyDelete